Cylinder Thread Viewer – Package

$300.00

Cylinder thread inspections with precision and accuracy EVERY TIME. {scroll to bottom of description for YouTube demonstration}. The Cylinder Thread Viewer assists you with inspecting cylinder threads in ALL cylinders.

The Cylinder Thread Viewer uses a threaded index plate for stability and a laser to pinpoint issues. It has an 8 hour rechargeable battery for extended use. Plus, all of this comes in a custom carbon fiber zippered case.

BUY YOURS TODAY

Improving Cylinder Inspection Tools

As technology improves, so too should our cylinder visual inspection tools. For this reason, Cylinder Training Services is touting the Cylinder Thread Viewer. Inspecting high pressure cylinders, cylinder threads, and other areas of a cylinder is crucial for safety. We don’t take safety lightly.

And while cylinder thread inspections are not performed with regularity, it is a routine that a user has to keep up with. After all, inspecting the cylinder threads is something that needs to be done on a regular basis. There is a misconception that inspections are only done at the start of a tank’s service. However, this is not the case.

If you are wondering how often a cylinder should be visually inspected, the answer is as often as there is a concern. A hydrostatic test can be completed every five years. But issues may come up before the hydrostatic test date.

When it comes to safety, and the quality of your cylinders, the ongoing motto should be “inspected and tested.” With this Cylinder Thread Viewer, you can do precisely that.

For more information about what this cylinder inspection tool consists of, continue reading on. Or, scroll all the way down for a video on how it works.

Description

Cylinder Training Services has developed a new tool to help the inspector view a cylinder’s threads. Traditionally, many inspectors use a light and mirror to perform a cylinder thread inspection . This procedure has been used for a long period of time but takes dedication and practice to master the techniques.

Additionally, using a light and mirror in this way can be problematic for people with diminishing eyesight. To overcome these issues Cylinder Training services has developed the Cylinder Thread Viewer.

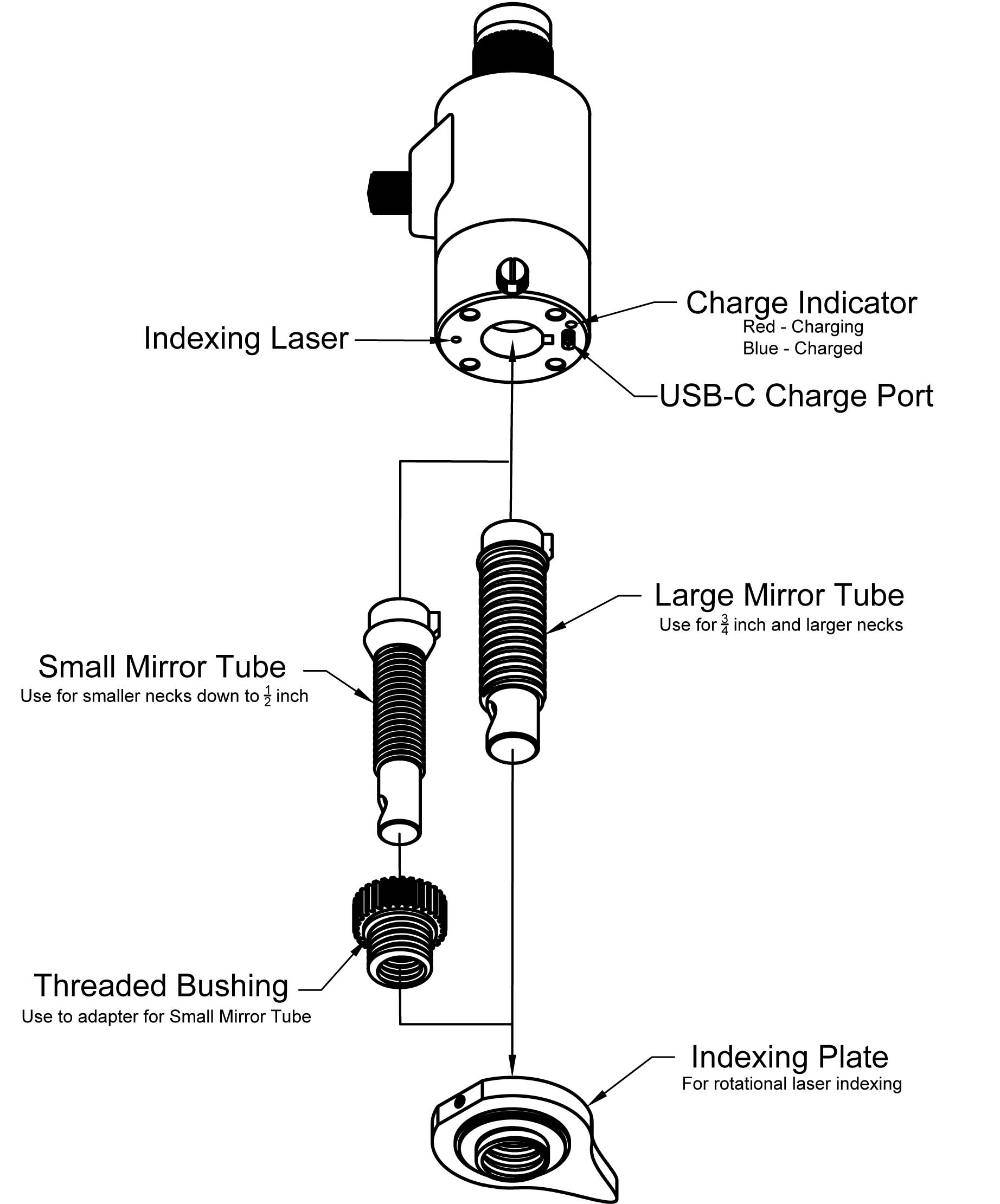

The Cylinder Thread Viewer helps the inspector by clarifying, magnifying, modifying, and simplifying the inspection process. This is all accomplished using a laser on an index plate, rechargeable batteries, Glass lenses and interchangeable mirror tube sizes.

After all, visually inspecting a cylinder shouldn’t be a challenge or a fine art. though a particualr process, it should be routinely done, and done efficiently. This was the goal of Cylinder Training Services, and we feel we have accomplished it with our Cylinder Thread Viewer.

Clarify

The clarity of the cylinder threads is very important during the cylinder inspection process. The Cylinder Thread Viewer uses an internal white LED light to highlight the peaks and valleys of the threads. The intensity of the LED light can be adjusted using the front Off/On knob.

As the knob is turned on, the intensity of the light increases. If the light becomes too intense, the knob can be adjusted, giving the inspector a customized view of the cylinder threads. The clarity of the threads can be focused, using the adjustable focus tube. The user can adjust the view based on their personal vision needs.

While it might sound like a simple fix, these adjustments to the Cylinder Thread Viewer make a significant difference during the cylinder inspection. But, Cylinder Training Services did not stop there.

Magnify (1X)

Looking through the focus tube, the Cylinder Thread Viewer, uses high quality glass optics. The custom optics were designed and produced by a high-end optics company. The mirror used has no magnification (1X)

However, as the user adjusts the LED white light and focuses the tube for a clear view, the glass optics reveal the threads in a crisp clear Picture. Similar to wearing reading glasses to clear up the vision when something is closer to the eye.

Again, this attention to detail is a game changer for cylinder inspection tools.

Modify

As you move the Cylinder Thread Viewer deeper into the threads, and into the interior of the cylinder, the inspector can view the underside of the cylinder crown.

As you move the viewer, you can continually adjust the focus. The mirror and optics have a field view of 2 inches / 5 centimeters. Thanks to this focusing ability and the brightness of the light, the inspector can see the underside of the crown and check for possible cracks or excessive corrosion.

The Cylinder Thread Viewer also can change the diameter of the mirror tube. Two tube sizes can be added to the system. One has a diameter of ¾ inches / 2centimeters and one goes as small as ½ inch / 1.25 centimeters. the inspector can choose the best mirror size for the cylinder they are inspecting.

Just like all cylinders are not the same size, the cylinder inspection tools should be adaptable to be as efficient as possible. As you see, Cylinder Training Services’ Cylinder Thread Viewer has it covered.

Simplify

To use the Cylinder Thread Viewer the inspector:

- chooses the size of mirror tube

- places an index plate on the top of the cylinder

- turns the viewer on

- screws the threaded mirror tube into the cylinder index plate.

The cylinder index plate ensures the mirror tube is stabilized. The index plate threading has been custom designed for this purpose. Specifically, it uses as few rotations as possible while still allowing multiple passes of the threads. Therefore, the inspector and the cylinder remain in their respective position, and the only thing that turns is the Cylinder Thread Viewer.

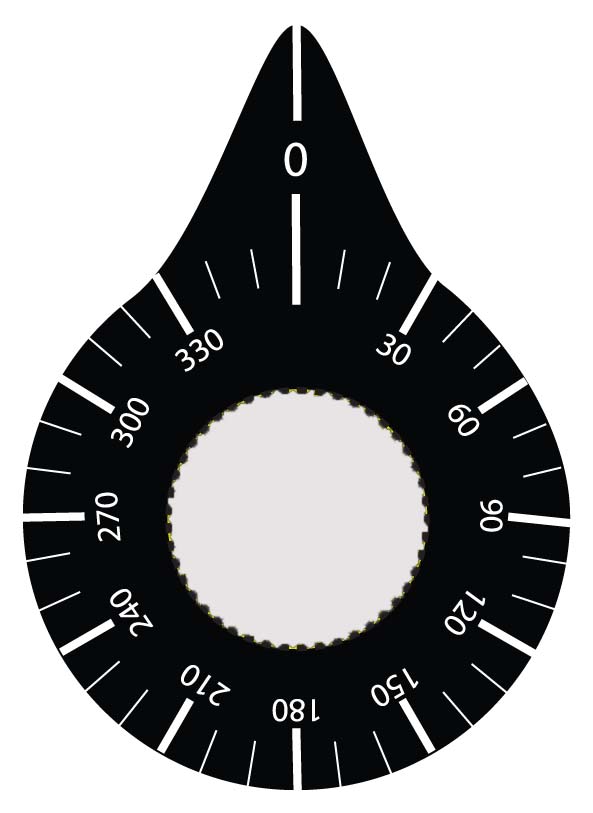

Additionally, the Cylinder Thread Viewer has a custom label on the index plate and an internal laser guiding system. These attributes help identify areas of concern.

The index plate has a point, which is set on a specific location on the cylinder. For example, the point can be placed on the first letter/number of the serial number. That becomes the “O” point.

As the unit is rotated the laser tracks along the index plate. When teh inspector notices something, they look at the cylinder index plate and record the number on which the laser lands. That allows them to locate the same location when re-assessing the cylinder threads or crown.

This is an excellent cylinder inspection tool when identifying the difference between a tap Stop mark and a crack. Review the latest Cylinder Training Services BLOG – Do Not Condemn a good cylinder.

And yet, one of the greatest simplification tools added to the Cylinder Thread Viewer is the rechargeable battery. It is no secret that a cylinder inspection tool is only effective if it has power. Further, it is important that this charger be adaptable, which is why it works with a standard USB-C

Using a USB-C charging cable you can rapidly charge the unit for 8 hours of continued use. No need to take the unit apart and find batteries for replacement. Simply charge and use. If it is accidently left on, conduct a quick re-charge to continue with the inspection process.

Scuba Cylinder Visual Inspection Tools are worth it

There is no denying the importance of this technology, and the safety required when it comes to inspecting high pressure cylinders. With the right equipment and tools, the inspection can feel routine while also putting you at ease.

Reach out to learn more about Cylinder Training Services’ Cylinder Thread Viewer, or order your own today.

Cylinder Thread Viewer – PRINTABLE MANUAL

| Weight | 1.0 lbs |

|---|---|

| Dimensions | 10 × 4 × 3 in |

You may also like…

Related products

-

Lighting / Inspection Tools

Valve O-Ring Size 112

$10.00 – $18.00 Select options This product has multiple variants. The options may be chosen on the product page

Reviews

There are no reviews yet.