Cylinder Inspection Training: Why a Maintained Cylinder Is a Happy Cylinder

Uncover the importance of gas cylinder inspections and training. Dive deep into ensuring safety, boosting efficiency, and prolonging cylinder life.

Medical oxygen is a life-saving gas that is used in various medical treatments, such as respiratory therapy, wound care, SCUBA Diving injuries and resuscitation. Oxygen is stored in high-pressure cylinders and is distributed through a oxygen regulator to the patient. Understanding the markings on a medical oxygen cylinder is crucial for both healthcare professionals and users, as it provides information about the cylinder’s contents, and pressure ratings.

In this article, we’ll take a closer look at the markings and labeling on a medical oxygen cylinder and explain what they mean. We’ll also discuss the different types of medical oxygen cylinders, their capacity, and the importance of using the right cylinder for the right application. By understanding the markings and labeling on a medical oxygen cylinder, you can ensure that you’re using the right cylinder for your needs and that you’re using it safely and effectively. Whether you’re a healthcare professional, SCUBA Diver or a patient, this information will help you make informed decisions about your oxygen therapy.

Most medical oxygen cylinders are designed to be transported on the highway system. Whether it is an Oxygen supply tank or a cylinder used in a home, it must get from point A to point B. All high pressure cylinders are required to have specific markings embedded on the cylinder for this transportation. There are currently 6 specific markings that the manufacturer places on the cylinder before it enters the users hands. If the cylinder is missing any of these 6 markings, the cylinder can not be used or filled at a commercial facility.

Other marking may be added later, such as the 5 year hydrostatic requalification, which is a government mandate. The user can also add their own markings and symbols, as long as it does not damage the cylinder.

Most oxygen cylinders have the color green. Whether it is the entire cylinder, or just a green paint across the top of the cylinder. Oxygen is considered a CLASS 2 gas by the government and may have a label stating such. The HAZMAT Class 2 in United States law includes all gases which are compressed and stored for transportation. You might also see placards on commercial vehicles in the green diamond shape.

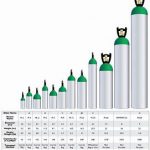

Oxygen cylinders come in a variety of sizes. Some as small as a few liters for specialized purposes such as aviation oxygen for pilots. However, more common sizes are used for general use. The size of the cylinder is determined by the length of time the user requires. Size can determine capacity. Capacity is determined by the length of use, which can be controlled by the flow through the regulator. Another consideration is the weight and size if a user will be carrying the cylinder.

It is important to balance the needs of the user with the cylinder capacity. Even if the user reduces the flow of the oxygen through the regulator to a few liters per minute, it will eventually empty the cylinder. The best calculation for sizing a cylinder is by knowing the flow rate required by the user. Use a cylinder that has the capacity to feed oxygen to the user for the required amount of time.

Cylinders are designed to be safely transported and used. However, don’t forget that the cylinder is pressurized and contains an oxidizing gas. Dangers are present when using or filling a cylinder. Common sense things to remember is not to drop the cylinder, don’t use it around flames and ensure that it is inspected for damage on a regular basis by a trained cylinder inspector or hydrostatic requalifier. And, when needed, only get it filled by a trained fill station technician.

I enjoy continuing to build the business based on safety since 1999. CTS focuses on the inspection of high pressure cylinders, the maintaining of the valves and basic maintenance of high pressure compressor systems. CTS stays current in techniques and tools to train both the new and novice employee. We publish articles, update training tools and have created an APP to assist during the inspection process.

#cylinder #safety #hazmat #training #cylinderinspectiontraining #cylindex

Uncover the importance of gas cylinder inspections and training. Dive deep into ensuring safety, boosting efficiency, and prolonging cylinder life.

Is your composite cylinder showing signs of wear? Discover when to seek a professional repair service in our comprehensive guide.

29 CFR 1910.101 intro Handling cryogenic cylinders involves working with extremely low-temperature gases that pose unique safety risks. To ensure the safe handling, storage, and transportation of these hazardous materials,

Introduction Firefighters encounter many risks while on duty, including hazardous materials and high pressure bottles. High pressure bottles are used for a variety of purposes in firefighting, including powering hydraulic