Cylinder Inspection Training: Why a Maintained Cylinder Is a Happy Cylinder

Uncover the importance of gas cylinder inspections and training. Dive deep into ensuring safety, boosting efficiency, and prolonging cylinder life.

There is some misunderstanding when it comes to high pressure cylinders and inspections versus requalification’s. Those in the SCUBA dive industry are told that their cylinders must be inspected on an annual basis. Other high pressure cylinder users; such as fire departments, laboratories, aviation and beverage, rely solely on the 5-year requalification process. In either circumstance the more frequently you inspect the cylinder the less likely an unsuspecting issue will develop. The SCUBA industry has practical reasons for the annual inspections. Other industries have legal reasons for the 5-year re-qualification process. No matter which standard or regulations you follow, how would a cylinder owner know that the inspection was completed or the requalification completed properly and by a registered requalification facility? The owners/users only see a stamp, label or sticker. How does the owner / user know if they have paid for a service which may have never been performed? Or worse, paid for a service performed by an unauthorized facility.

In regards to annual inspection stickers on a SCUBA cylinder, the trust may have to come from a relationship with a specific facility. There is no governing body which distributes specific stickers and/or tracks them in a system. Individuals can make their own sticker or purchase them from a plethora of commercial printers or facilities. The specific relationship with a facility will hopefully alleviate some doubt as to the inspection performed or the quality of that inspection. The close relationship may also act as a deterrent to the facility not to make a mistake on a valued clients cylinders, or try to use short cuts.

Hydrostatic requalifier’s work differently. Licensed hydro-testers must complete federally approved training and they must register with the Pipeline and Hazardous materials safety administration (PHMSA), a division of the Department of Transportation (DOT) in the United States. Other countries also have strict regulations to become a hydrostatic requalifier and maintain that qualification. Once a business becomes a government licensed hydro-test facility, they must follow the regulations or face fines and penalties for errors or mistakes.

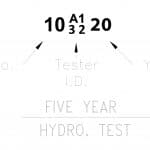

In the United States a licensed facility is provided a Requalifier Identification Number (RIN). The RIN has one letter and 3 numbers, and is specific to each facility. (see example below). If the facility is in compliance with the regulations the government maintains a record of active RIN holders. If the facility has problems, complaints, or is not in compliance, the government may impose fines or revoke the RIN.

If the RIN is not valid, how is the user to know? The answer is easy. The DOT maintains a list of active RIN holders on their website: https://portal.phmsa.dot.gov/rinlocator . This locator will help you to determine if the facility you use for requalification’s is current and valid. If you have any questions about the facility the link gives you the ability to send a query to the DOT asking specific questions.

The below picture is an example of a facility or person who was not authorized to requalify a cylinder. If you look at the stamp it does not meet the requirements listed in the above example. If you were to try and type in this RIN (GE81) it would not come up as valid on the DOT website. However, the owner paid this facility for a requalification, and unbeknownst to them, the cylinder most likely was never tested. That left the owner, and anyone else who may have used or filled that cylinder, exposed to hazards.

Anytime you use a facility to requalify your equipment, ensure that they have the proper documentation and credentials. If they are not valid, it is likely that they won’t be around to take the brunt of any legal actions and will likely not help in paying for a requalification. The simple step of verifying the facility could save you hundreds, or even thousands of dollars, depending on the number of high pressure cylinders requiring requalification.

Author – Don Kinney

About the author: Don Kinney is the owner of Cylinder Training Services (www.cylindertrainingservices.com). He started commercially working with cylinders in 1991. With his background in public safety he continued to gain knowledge in the field of high pressure cylinders and began to develop training programs. He has developed cylinder training programs for the fire service, diving, beverage, aviation and hydrostatic requalifier’s. His latest program qualifies persons to use Eddy Current instruments and is endorsed by AIT. Visit www.cylindertrainingservices.com for more information on courses and a full line of inspection equipment.

I enjoy continuing to build the business based on safety since 1999. CTS focuses on the inspection of high pressure cylinders, the maintaining of the valves and basic maintenance of high pressure compressor systems. CTS stays current in techniques and tools to train both the new and novice employee. We publish articles, update training tools and have created an APP to assist during the inspection process.

#cylinder #safety #hazmat #training #cylinderinspectiontraining #cylindex

Uncover the importance of gas cylinder inspections and training. Dive deep into ensuring safety, boosting efficiency, and prolonging cylinder life.

Is your composite cylinder showing signs of wear? Discover when to seek a professional repair service in our comprehensive guide.

29 CFR 1910.101 intro Handling cryogenic cylinders involves working with extremely low-temperature gases that pose unique safety risks. To ensure the safe handling, storage, and transportation of these hazardous materials,

Introduction Firefighters encounter many risks while on duty, including hazardous materials and high pressure bottles. High pressure bottles are used for a variety of purposes in firefighting, including powering hydraulic